IGM402 Hornet™ Hot Cathode

Overview

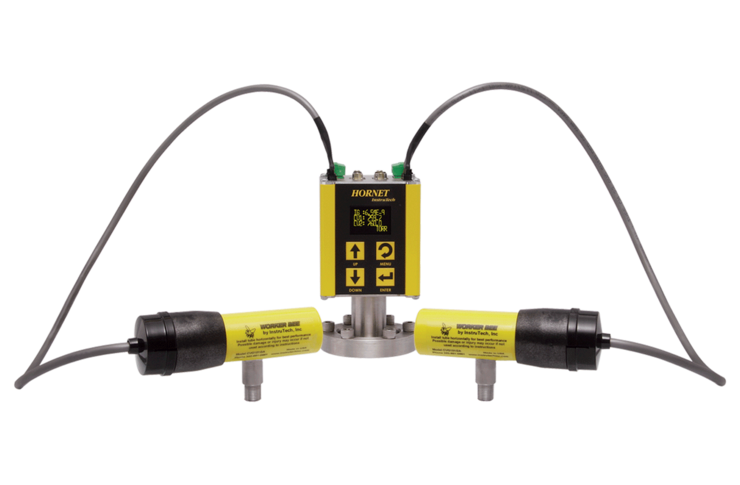

IGM402 Hornet is the first modular miniature hot cathode Bayard-Alpert ionization vacuum gauge capable of operating 1 ionization and up to 2 convection gauge sensors simultaneously. The pressure measurement range of the IGM402 is 1.00E-09 to 1,000 Torr.

The IGM402 can combine the vacuum measurements from the ionization gauge and one of the convection gauges to provide full range vacuum measurements from high vacuum to atmosphere, or simply operate the ionization gauge and the 2 convection gauges as individual gauges.

IGM402 is available with various fittings including NW16KF, NW25KF, NW40KF, 1 1/3 in. Mini-Conflat, 2 3/4 in. Conflat, 3/4 in. O.D. Tube (O-ring compression) and 1/2 in. Cajon 8VCR female.

Features

- Full measurement range of 1.00E-09 Torr to 1,000 Torr

- Built-in controller with bright 3-channel OLED digital display

- User programmable display units in Torr, mbar or Pa

- Operates 1 ionization and up to 2 convection vacuum gauges

- Significant cost savings in controller, foot-print, cabling and sensor replacement

- 3 analog outputs and 3 setpoint relays

- RS485 serial communications

- CE and RoHS compliant

- Standard warranty of 18 months

Optional Power Supply

FAQ

What is the principle of operation?

The hot cathode Bayard-Alpert ionization vacuum gauge operates by ionizing the gas inside the gauge and then measuring the number of ions generated. The ions are then collected giving a measurement of the density or pressure of the gas inside the transducer. The various electrodes used in the transducer design are a collector surrounded by a circular grid with one or two filaments outside the grid.

An electric current is passed through the filament to cause the filament temperature to increase. As the filament temperature is increased, electrons are emitted from the filament surface. The bias voltage between the filament and the grid will accelerate the electrons toward the grid. Most electrons will pass through the grid volume and exit the other side of the grid and then be drawn back into the grid for another traversal through the grid volume. Eventually, most electrons will impact the grid surface generating a current between the filament and the grid which is referred to as the emission current. The electronic controller is designed to maintain a constant, selectable emission current which is independent of pressure. While an electron is traversing inside the grid volume, it may collide with a gas molecule and ionize it which removes an electron. The ionized gas molecule, which now has a positive charge because it is missing an electron, will be attracted to the collector which is at ground potential. A current will be generated by the flow of ions to the collector which is known as the ion or collector current. An electrometer will measure the small ion current generated and a pressure, which is proportional to the ion current, can be calculated.

What is the measurement range of the IGM402?

- 1.00E-09 to 1,000 Torr

- 1.30E-09 to 1,333 mbar

- 1.30E-07 Pa to 133 kPa

Why is the IGM402 referred to as a “Module”?

A module is a complete vacuum gauge which combines the sensor and electronics (controller) in one assembly requiring no external controller to operate. The IGM402 is a vacuum gauge module with a built-in controller, display and it also provides process control signals.

What is the ion gauge with dual convection mean?

The IGM402 is the first modular ionization vacuum gauge capable of operating two convection gauges simultaneously. The IGM402 Hornet can combine the vacuum measurement from the ion gauge and a convection gauge to provide wide range measurements from 1.00E-09 to 1,000 Torr, or simply operate the ion gauge and the two convection gauges as individual gauges.

What is the power requirement of the IGM402?

20 to 28 Vdc, 15 W. Users can provide their own power supply or use InstruTech’s optional power supply PS501-A

What is meant by the term “emission current”?

Emission current is the quantity of electrons emitted from the filament into the space inside the ion gauge transducer. The emission current can be changed to allow optimized operation of the ion gauge transducer at lower or higher vacuum. In general in higher pressure ranges of 5.00E-06 Torr to 5.00E-02 Torr the 100 uA emission setting is preferred. At lower operating pressure ranges of 1.00E-09 Torr to 1.00E-04 Torr the 4 mA emission current setting should be used.

What are the available output signals from the IGM402?

3 analog outputs, 3 setpoint relays and RS485 serial communications

What filament materials are available?

InstruTech offers two different filament materials.

1. Yttria Coated Iridium

2. Tungsten

Which filament material should I use?

For general vacuum applications, yttria coated iridium filaments are offered for use with inert gases such as air, Nitrogen, argon, etc. Tungsten filaments are available for use with gases that may not be compatible with yttria. The other tradeoff between the two filaments is that the tungsten filament will not survive accidental venting to atmosphere whereas yttria will. It is very important to make sure the tungsten filament is turned off before bringing the chamber up to atmosphere, especially if air is being used to vent the chamber.

How many filaments are there?

The IGM402 is offered with standard dual filaments.

How do I switch between the two filaments?

You can select which filament to turn on using the IGM402 front panel push buttons. We recommend periodic switching of the filaments every few months.

At what pressure can I turn on the filament?

If emission current is set to 100 uA, the filament can be turned on when pressure drops below 5.00E-02 Torr.

If emission current is set to 4 mA, the filament can be turned on when pressure drops below 1.00E-03 Torr.

Can I turn on the filament manually?

Yes you can turn on the filament manually using the front panel push buttons.

Can I turn on the filament automatically?

You can configure the IGM402 so the pressure measurements from one of the convection gauges can be used to automatically turn on the filament. You can also use digital inputs or RS485 serial communications commands.

What does degas mean?

Degas is used to rid the gauge sensor of adsorbed gas. Degas is achieved by applying Electron Bombardment (EB) to the grid. The sensor’s low pressure performance will normally improve after each degas cycle.

When can I apply degas?

Degas must be applied while the filament is turned on and operating. Ensure vacuum level is at or less than 5.00E-05 Torr before attempting to initiate degas.

How do I initiate degas?

You can apply degas using the IGM402 front panel push buttons. You can also use digital inputs or RS485 serial communications commands.

Trademark Acknowledgements listed in the IGM402 Data sheet.